GRONNE BJERG ANORTHOSITE PROJECT

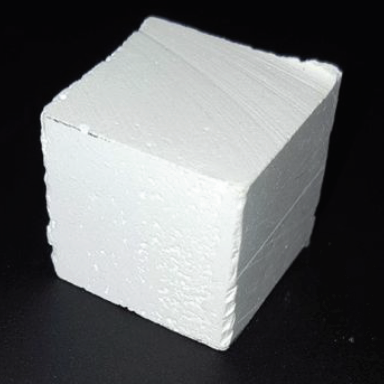

What is Anorthosite?

Hudson’s Gronne Bjerg anorthosite is a calcium feldspar rock which is primarily comprised of aluminum (32%), silicon (47%) and calcium (15%).

Multiple Revenue Streams

E-Glass

A replacement for kaolin in the production of E-glass fiberglass. A 10 year off-take agreement has been signed with a leading fiberglass producer.

Paint & Polymer Fillers

A replacement for kaolin and nepheline syenite in paints, coatings and polymers.

Source of Alumina

A replacement for bauxite as a primary source of alumina without producing any waste or tailings.

Cement

A replacement for Portland cement to produce Anocrete, a CO2 free white cement.