PRODUCTS

Chemical Analysis

(Based on 2022 sampling at Gronne Bjerg)

| Silicon Dioxide (SiO2) | 47.24 |

| Aluminum Oxide (Al2O3) | 32.06 |

| Iron Oxide (Fe2O3) | 1.15 |

| Sodium Oxide (Na2O) | 2.27 |

| Potassium Oxide (K2O) | 0.43 |

| Magnesium Oxide (MgO) | 0.70 |

| Calcium Oxide (CaO) | 14.98 |

| Loss on Ignition (LOI) | 1.00 |

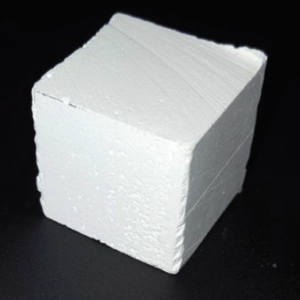

Anorthosite is composed of 90% Plagioclase Feldspar, formed in a low quartz environment resulting in a dense and consistent formation, with less than 10% being other minerals. Purity levels increase with the removal of iron bearing micas during processing which results in a monomineralic Anorthite. The chemical formation is very stable oxides, with no detectable alpha quartz, resulting in an advantageous Calcium Alumina Silicate final product with no free silica.

The mineral Anorthite (CaAl2Si2O8) is a rare compositional variety of plagioclase and has the highest density of all feldspathic minerals, and yields the hardest feldspar with the highest refractive index. These unique properties gives Anorthosite a distinct advantage as a premium mineral extender for interior paints requiring very good abrasion resistance. It also can result in a stronger finish and cost savings as resin filler in clear coatings.

Product Applications

E-Glass Fiberglass

Anorthosite is a replacement for kaolin in the production of E-Glass with significant technical, financial and environmental advantages.

- Energy savings of +10%

- Reduced melt time by up to 33%

- Lower heavy metal content

- Lighter stronger fibers with less waste

- Reduced NOx, SOx and CO2 emissions

- Reduced wear and tear on refractories

- E-Glass fiber is most commonly used in the reinforced polymer composite industry – Used in high-end fiberglass for wind turbines, cars and boat parts, sporting equipment.

- Major markets concentrated in Asia, Europe and USA. E-glass fiber market is expected to grow to US$17.4 billion by 2024.

White CO₂ Free Cement

Hudson has discovered that adding phosphoric acid to our anorthosite produces a strong, heat resistant white cement.

- No addition of CO2 to the environment. Portland cement adds 0.9 tonnes of CO2 to the environment for every tonne produced

- Initial findings show the cement to be at least as hard as Portland cement (30 Mpa) and a very high tolerance to heat (1000ºC)

- The anorthosite cement is more acid resistant than ordinary Portland cement

Paints and Coatings Applications

Anorthosite is an excellent mineral additive for the paint, coatings and polymer industries which are expected to grow to US$31.8 billion industry by 2023.

Anorthosite is a superior feedstock for fillers in paints based on the following benefits:

- Lower oil absorption (by up to 20% over nepheline syenite)

- High brightness (ISO 89%)

- High level of hardness for abrasion resistance

- High refractive index that mirrors major polymers and wood coatings

- Low crystalline (free) silica

Alumina Potential

- Alumina (Al2O3) is primarily used as a feedstock for the production of metallurgic grade aluminum

- Can produce alumina from Anorthosite with no waste products unlike bauxite, which produces two tonnes of toxic waste for every tonne of alumina using the Bayer Process.

- Needs to be processed outside of Greenland due to energy costs and chemical requirements

- Global high purity alumina market was worth US $1.8 billion in 2015 and is expected to reach US $5.8 billion by 2022